hotline:

13802460607

web:www.sampe.com.cn

tel:0750-3683330

contacts:Miss Tan

email:sales@sampe.com.cn

hotline:

13802460607

web:www.sampe.com.cn

tel:0750-3683330

contacts:Miss Tan

email:sales@sampe.com.cn

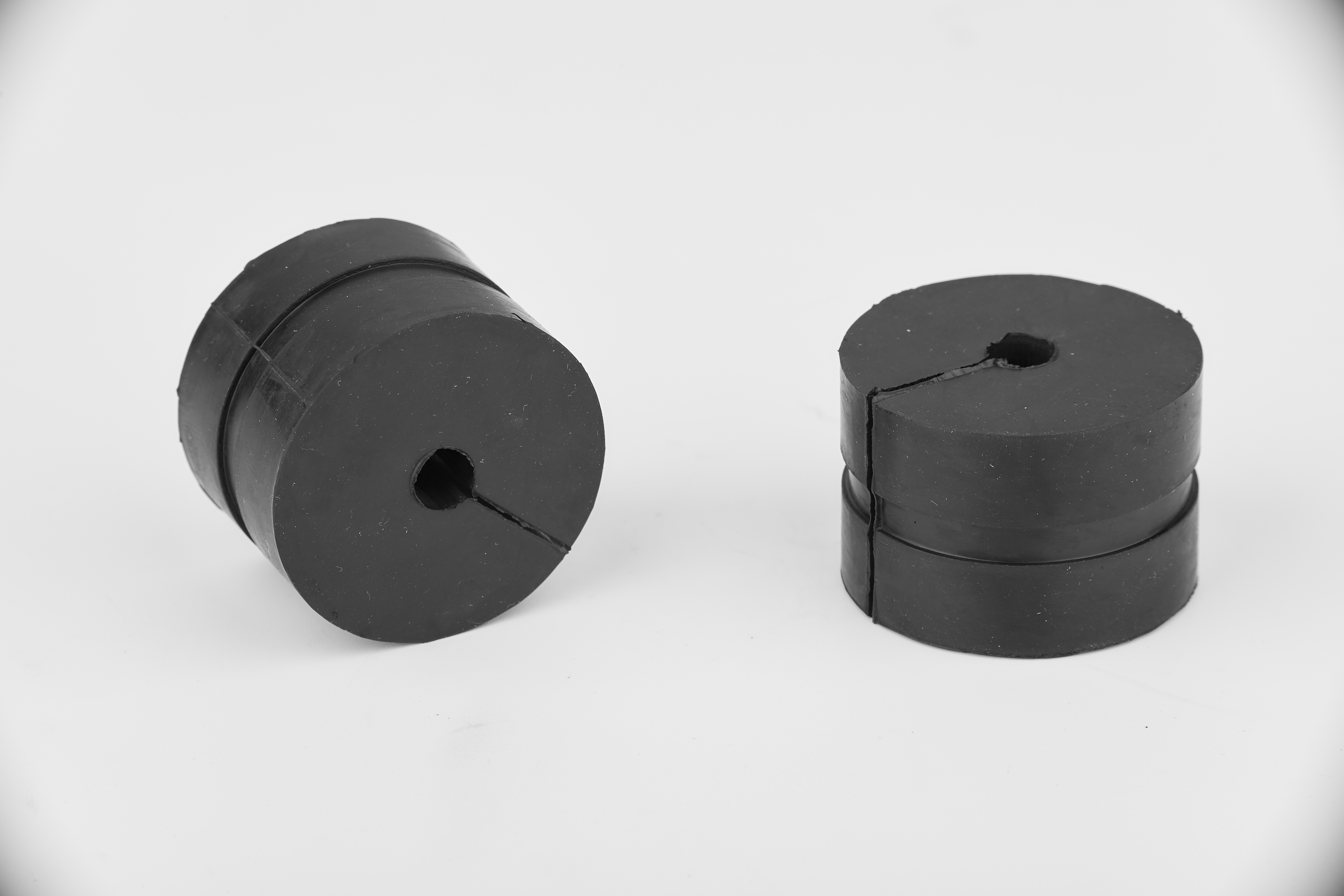

1. Rubber parts are hot-melt elastomers, plastics are hot-melt and cold-solid. Because of the different types of vulcanizates, there will be a certain gap in the curing temperature range of rubber, and it can even be changed by climate changes, and indoor temperature and humidity will also have an impact. Therefore, the production conditions of special-shaped rubber parts processing parts need to be adjusted at any time. If there is no, the quality of rubber parts may be different.

2. When the special-shaped rubber parts are processed and molded, they have undergone huge suppression, because the cohesive force of the rubber seals' elasticity cannot be eliminated. During the molding process, they often produce extremely unstable shrinkage, which must go through a period of time. After a period of time, it can be relieved and stabilized. Therefore, when designing rubber seals, no matter the formula or the mold, it is necessary to carefully calculate the fit. If not, it is very easy to cause the size of the rubber seal to be unstable and reduce the quality of the rubber accessories.

3. The processing of special-shaped rubber parts requires the rubber raw material to be mixed with the rubber raw material after the internal mixer is used as the raw material. When mixing the rubber, the formula needs to be made according to the characteristics of the rubber seal, and the required product hardness is set . Special-shaped rubber parts are processed and molded by a rubber plate vulcanizing machine. After the special-shaped rubber parts are processed and formed, flashing treatment is required to make the surface of the product smooth and thorn-free.